The Importance of Radiation Protection Across Industries

Radiation Protection is an important field across a wide range of industries, from healthcare and medical imaging to nuclear energy, nuclear medicine, and non-destructive testing. ALARA (As Low As Reasonably Achievable) is a principle that strives to minimize the exposure of ionizing radiation to people and the environment while considering economics, technology and social factors. Considering all the factors, and the number of materials to choose from, consulting with a shielding materials expert is essential to finding the most effective solutions to your shielding needs.

Choosing the Right Shielding Material

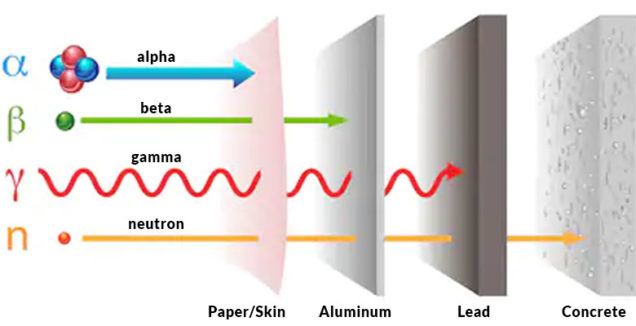

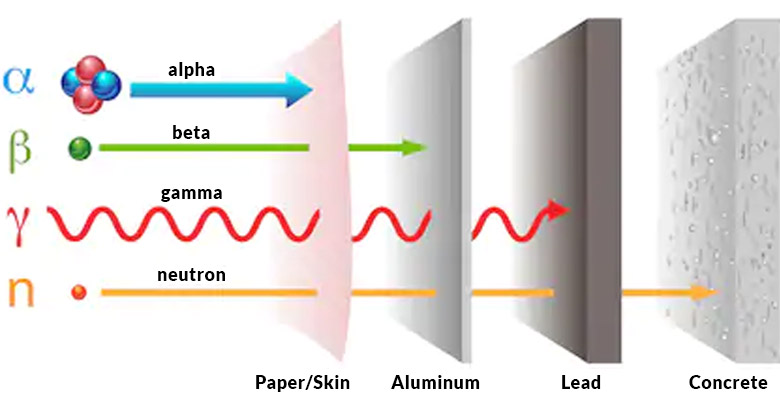

It all starts with the type of radiation that is present. Materials interact differently with different types of radiation. For example, tungsten is able to attenuate gamma radiation effectively, but when exposed to neutron radiation, secondary gamma rays can be produced. Materials that are strongest at attenuation gamma radiation are tungsten and lead, while high density concrete and borated polyethylene are better materials for stopping neutrons.

Factors to Consider for Radiation Shielding

Choosing the right material will allow you to save space and use less material. A shield of high-density concrete can take half the space of regular concrete with the same shielding properties. Flexibility of a material is also important to think about when considering the space requirements. A flexible material like metal impregnated polymers might be more suitable to shield a round object like a pipe, as it can be wrapped around tightly.

Environmental Conditions for Shielding Materials

The environmental conditions that the shielding is placed in is also important to consider. How well a material can withstand heat, if the shielding will be moved and potentially bumped and if the material must hold any structural load are all important factors in the environment that need to be considered. Shielding properties can change when put under stress or heated. Dents and damage to the material may also lessen the ability for a material to shield properly.

Costs of Radiation Shielding

Cost is an important to consider when selecting the appropriate shielding material for a job. Lead is a very effective and inexpensive shielding material compared to materials like tungsten and could work just as well for a lot of scenarios. Related to cost, another factor that needs to be considered is the ease of shipping, handling, and installation. Choosing between installing leaded drywall or sheet lead is one example where shipping and installation need to be considered.

Radiation Shielding Safety & Protection

Radiation Shielding Safety & Protection

Safety is important in selecting the right shielding solutions. Leaded glass for example comes in several options including safety glass. Clear Leaded Acrylic is also a viable option to making durable clear shielding that is shatter resistant. Exposed lead may not be permitted in some scenarios due to the toxicity of lead, so polymers mixed with bismuth, tungsten or iron may be a better, non-toxic alternative.

Find the Right Radiation Shielding Solution With MarShield

When protecting people and the environment from radiation, knowing what materials are available is key to finding the right shielding solution. A lot of factors need to be considered when choosing the right material, which is why a material expert becomes an important part of any radiation shielding design team. In the coming series of articles, we will go through the materials mentioned above and talk about the strength, weaknesses, and applications of different shielding materials. In the meantime, if you want to learn more about different types and application of materials, the MarShield website is a great resource on radiation safety materials or you can contact MarShield to speak to a shielding materials expert directly if you have any questions.

The complete list of MarShield products is now available in an easily readable and downloadable PDF format.

Stay Updated with Radiation Shielding News

To stay updated with the latest news and insights on radiation shielding and get information on new products, safety tips, and expert advice on shielding materials, sign up for our newsletter.