MarShield lead brick shielding provides the best choice for construction where temporary, permanent shields or storage areas are required, offering you the flexibility in your design and construction choices. Lead bricks are ideal for adding additional shielding to existing rooms and can be used in new construction as a method to reduce wall or ceiling thickness to achieve space savings. Our high purity lead bricks are ideal for shielding effectiveness where maximum protection is required from X-Ray and Gamma Ray radiation. Our bricks are relatively smooth, clean and have a non-porous surface. Our lead bricks can be used for walls, caves, glove-boxes, hot cells or partitions, the transportation of radioactive materials, and nuclear shielding or simply as ballast weight. Bricks are available in a wide range of sizes, thicknesses and shapes to suit your application. They are commonly used for shielding when sheet lead is impractical or not available in sizes or thicknesses you may require. Straight or interlocking styles are available from our stock.

Did You Know This

Product Can Be Lead Free?

With Mars FlexShieldTM technology, we offer a safe and environmentally friendly solution to traditional lead-based products.It’s lightweight. Flexible. Customizable. And it’s the future, now.

![]()

In order to help our customers better estimate the lead brick requirements and associated material costs for their shielded room and facility construction projects, we now offer a 3D Room Modeling service. Click here for more details.

Available Types of Lead Brick

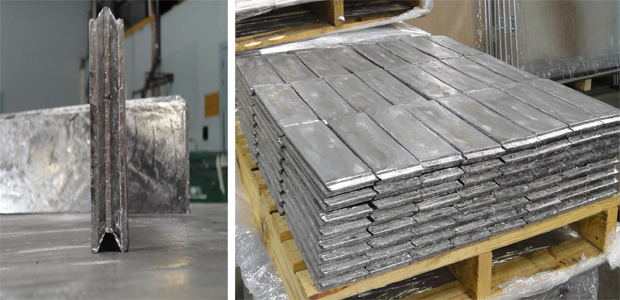

MarShield offers interlocking Chevron style bricks for maximum protection where the highest level of shielding is required for X-ray Beta and Gamma Shielding.

- Can be easily erected, modified, disassemble and relocated in the field to create protective walls systems and cells to suit your application.

- Unique interlocking “V” shape tongue and groove configuration prevents the leakage of radiation through gaps as commonly found in straight lead bricks.

- Provides a more stable and sturdier wall system aiding in the prevention of the wall toppling over.

- An efficient and tighter fit shielding when stacking or building wall systems.

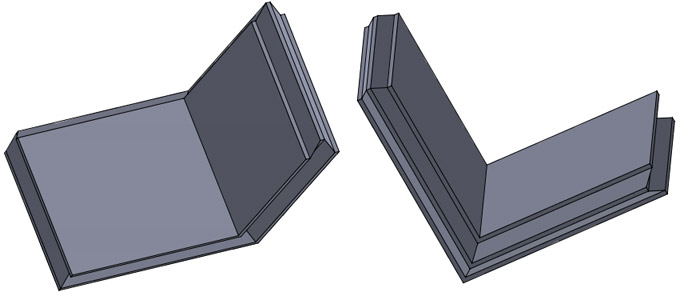

| Interlocking Lead Bricks | |

|---|---|

| Dimensions | Theoretical Weight |

| 3/4″ x 4″ x 12″ | 14.69 lbs. |

| 1″ x 4″ x 6″ | 9.79 lbs. |

| 1″ x 4″ x 12″ | 19.58 lbs. |

| 1-1/4″ x 4″ x 8″ | 16.32 lbs. |

| 1-1/4″ x 4″ x 12″ | 19.59 lbs. |

| 1-1/2″ x 4″ x 12″ | 24.48 lbs. |

| 1-3/4″ x 4″ x 12″ | 29.38 lbs. |

| 2″ x 4″ x 6″ | 19.58 lbs. |

| 2″ x 4″ x 8″ | 26.11 lbs. |

| 2″ x 4″ x 12″ | 39.17 lbs. |

| 1″ x 4″ x (2 ea 6″) Corner | 16.32 lbs. |

| 1-1/4” x 4” x (2 ea 6”) Corner | 20.39 lbs. |

| 2″ x 4″ x (2 ea 4″) Corner | 19.58 lbs. |

| 2″ x 4″ x (2 ea 6″) Corner | 32.63 lbs. |

Both .pdf and .dwg versions of our CAD drawings for interlocking lead bricks are available here.

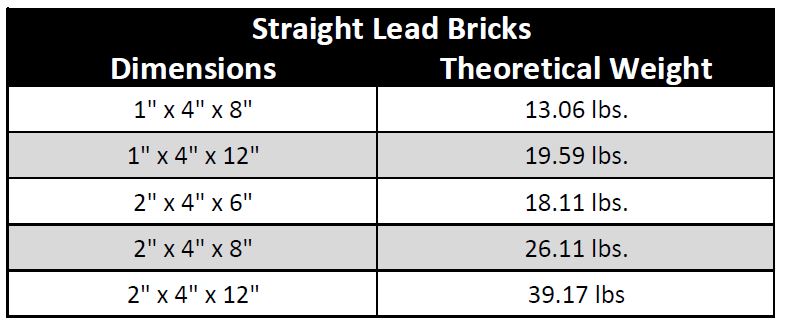

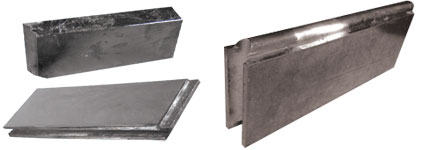

MarShield offers Straight type lead bricks for radiation shielding where interlocking bricks will not suit your application.

- Can be cut on site in any direction without the fear of losing the interlocking capability.

- A double row stacked behind the first in a staggered pattern can combat the loss of radiation commonly known to happen through the first row gaps.

MarShield offers Machined and Milled lead bricks in standard and custom sizes. Machined and Milled lead bricks are used for shielding radiation for industrial and medical uses, as well as for anti-corrosive linings.

Required Order Information

When preparing to order, please have the following requirements available:

- Size;

- Type of brick;

- Quantity.

![]() ”

”

Lead Bricks Information Sheet

Interlocking Lead Bricks – CAD drawings