MarShield has industry approved nuclear pouring procedures and is ISO9001:2015 and N299.3-16 certified (Equiv. to NQA1)

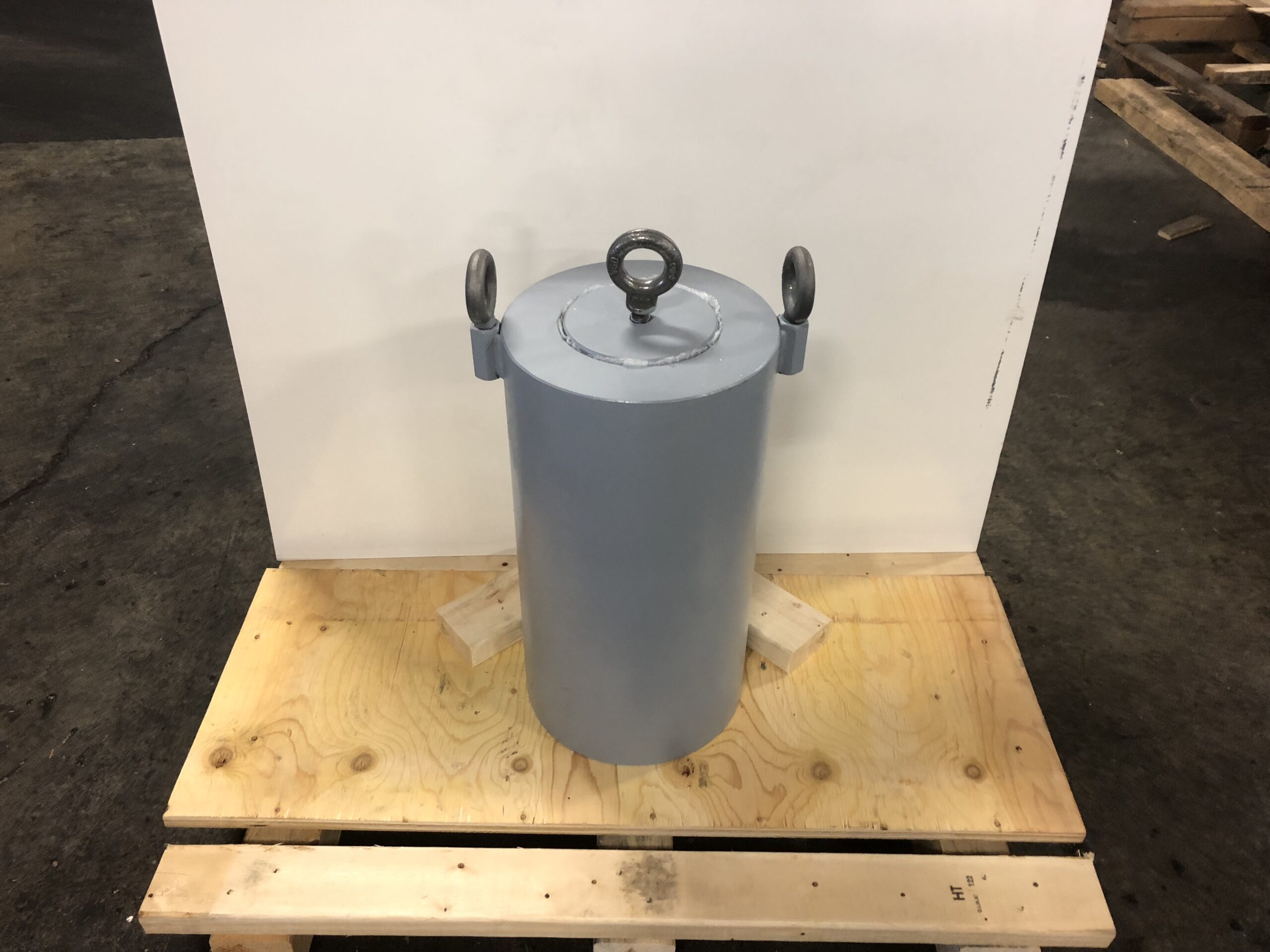

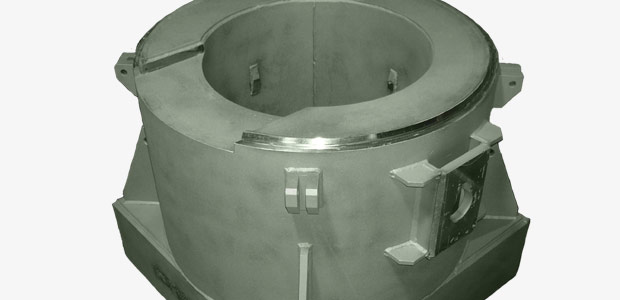

For over 40 years MarShield Radiation Shielding has been offering turnkey solutions to the nuclear industry including ASMT B29 lead pouring, fabrication, machining, cleaning, coatings and gamma testing. MarShield’s documented nuclear industry approved lead pouring procedures are in place that ensure a controlled temperature, shrink and porosity for a solid lead pour and maximum shielding protection. We are capable of pouring molten lead from 1 lb. to 100,000 lbs. For customer free-issued fabrications, we pickup and re-deliver to and from anywhere in the USA or Canada.

Quality Assurance

MarShield is ISO9001:2015 and N299.3-16 certified (equivalent to NQA1) and able to meet the most stringent of quality requirements. MarShield’s nuclear pouring procedure MMNP, used with supporting quality MSGNQAP procedures provides a fully documented and controlled nuclear pouring procedure that ensures control of source documentation, traceability, purchasing & vendors, CFSI (counterfeit, fraudulent and suspect items), lead receiving, verification of materials, responsibility, identification, pre-lead pour verifications, process and documentation, measuring devices, heat/temperatures of lead and steel, non-conformances, and inspection.

MarShield is ISO9001:2015 and N299.3-16 certified (equivalent to NQA1) and able to meet the most stringent of quality requirements. MarShield’s nuclear pouring procedure MMNP, used with supporting quality MSGNQAP procedures provides a fully documented and controlled nuclear pouring procedure that ensures control of source documentation, traceability, purchasing & vendors, CFSI (counterfeit, fraudulent and suspect items), lead receiving, verification of materials, responsibility, identification, pre-lead pour verifications, process and documentation, measuring devices, heat/temperatures of lead and steel, non-conformances, and inspection.