-

Lead Glass Shielding

MarShield carries a variety of sizes and thicknesses of lead glass that is excellent in providing radiation shielding. The material is usually placed into a lead-lined frame built into a wall or door. Lead glass is used extensively in x-ray rooms, operating theatres, radiation therapy rooms, dental clinics, veterinary clinics, laboratories and for materials testing. Applications include observation viewing windows and intercommunication windows, door glazing, panoramic glazing, mobile shielding protection, protection panels for check-up systems or in a mammography work station and as lenses for safety goggles.

-

High Quality, Transparent Lead Glass

MarShield’s lead glass has been designed to provide a high quality, transparent, protective shield against x-ray radiation. Extensive research and development has been done for you to trust its comprehensive protection in any medical or technical research application.

NOTE: The lead equivalent in mm – Pb, defines the protective effect of the glass compared to a lead wall. Example: A glass with 2.0 mm Pb offers the same protective effect as a 2 mm thick lead wall.

Click Here to view a Comparison of Lead Glass and Lead Acrylic (PDF)

More Lead Glass Info

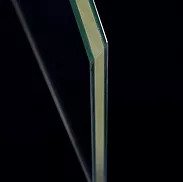

MarShield X-Ray Glass is a lead barium type glass of high quality optical grade with over 60 percent heavy metal oxide, including at least 55 percent PbO offering optimum performance. Our leaded glass provides excellent visual clarity while shielding against radiation from equipment in the 100 to 300 kV range. Both surfaces are mirror-polished, resisting abrasives and scratches. MarShield high quality lead glass is more than qualified to meet or exceed the high standards of stringent safety regulations established in the medical, scientific, as well as nuclear fields around the world. A continuous, automatic melting/rolling process allows production of lead glass in the industry’s largest size, 48″ x 96″ (1219.2 mm x 2438.4 mm).

Important Notes

General

- Lead glass cannot be tempered.

- Stickers and etching offered with lead glass ratings by request.

Receiving

- All glass must be thoroughly inspected upon receipt of goods.

- All discrepancies and/or damages shall be immediately noted and reported in writing to MarShield and on the freight bill of lading when received.

- It is then necessary to immediately notify the carrier’s head office of any damages. Please file any claims for freight damages with this carrier within 24 hours. MarShield will happily assist however possible, when requested.

- All materials received shall be properly stored in the original crate in which it is received until such time as the installation.

Storage

- X-ray leaded glass should not be exposed to humidity, temperature fluctuations or acid gases.

- The glass should only be stored in a vertical position and never laid flat.

- The room shall be properly ventilated to carry the dampness out of the room.

- Avoid any exposure to direct sunlight, extreme heat source, water, and humidity or excessive temperatures.

Installation

- Remove any protective plastic wrap prior to installation without sharp objects.

- When installing, care should be taken that the sealing agents do not contain any acid or alkaline substances (e.g. acetic acid, ammonia). Labels may cause staining on the glass surface by the reaction of the adhesive.

- Lead glass is extremely fragile compared to normal household glass and therefore should only be cut by an experienced glass cutter.

Cleaning

Due to the high lead oxide content, on some of our lead glass surfaces they will be more susceptible to scratching and the attack of acids and alkalis. Use only an approved, non-abrasive cleaning agent along with a soft cloth. The glass can be disinfected by using a commercially available disinfectant.