Radio Frequency (RF) waves are electromagnetic waves produced by electronic devices and networks such as cell phones or radio towers. RF waves can be shielded by enclosing an area with a conductive material and electronically grounding the shield.

The most common use of RF shielding in the medical industry is for Magnetic Resource Imaging (MRI), a non-invasive way to take 3D images of a person for diagnostic purposes. The MRI creates a strong magnetic field that aligns protons in the body and then detects the release of energy as the protons return to an equilibrium state, creating an image of inside the body.

There are two reasons imaging rooms are shielded from RF waves:

- To achieve the clearest possible image from the MRI, there needs to be minimal amounts of background RF waves.

- MRI uses a powerful electromagnet (usually 0.5 to 2.0 Teslas in strength) which produces RF waves that will cause interference with other electronics in the surrounding area, which can be very detrimental in a healthcare setting.

The shielding prevents RF waves from leaving the imaging room as well as blocking out background RF waves.

Materials and Methods Used for RF Shielding

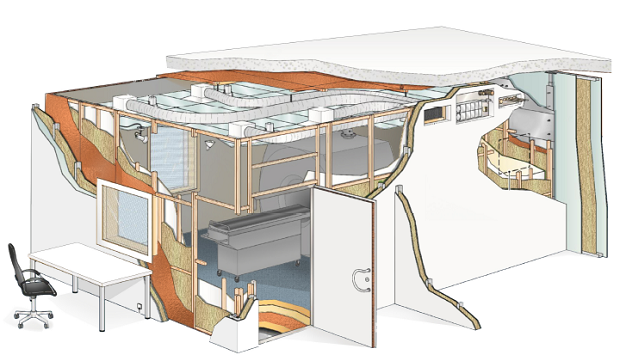

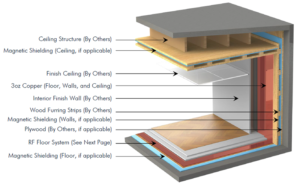

The most common metal used for RF shielding is copper because it has good conductivity. Copper sheets are attached to plywood and used to line the walls, floors, and ceilings of the MRI imaging room. The joints are then soldered together to create a conductive shield.

A more cost-effective method is to use galvanized steel bonded to a wood material core. The panels are then attached with steel framing joints. The downside of this method is that it is difficult to install in areas with restricted site access.

A room, however, typically has more than just walls. Doors are specially designed to maintain a conductive seal when the door is shut, and windows need to be made with glass with a thin double layer metal mesh. This affects the clarity through the window but still maintains the RF shield.

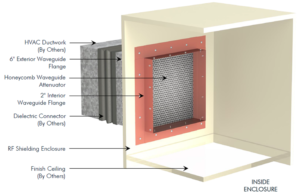

Finally, different utilities need access to the room, like electricity, HVAC and pipes for gas and water. Electrical wiring required in the room must pass through a power filter attached to the room’s common ground.

Testing the Room’s Quality

After the RF shielding is installed, it needs to be tested to ensure minimal RF noise in the environment surrounding the MRI equipment. Typically, to test for RF noise, a transmitter is placed outside the room that will transmit a certain frequency and strength of RF wave. A receiver is placed within the shielded room to determine how much of the signal penetrates the RF shielding. From testing, it can be determined if the joints or shielding need to be replaced or if the door’s conductive shield needs to be revaluated.

RF is important when installing an MRI machine to achieve optimal images and to reduce interferences with electronic equipment outside the room.

MarShield MRI/RF Systems

MarShield offers a variety of MRI/RF shielding systems:

RF Copper System: This non-ferrous enclosure is ideal for shielding applications with restricted site access. The lightweight copper makes for easy navigation through job sites with limited space. Copper sheets are attached to a plywood substrate, and the copper is soldered together at all seams. The plywood, framing, and support are completed by others.

The copper material is easily adaptable to various room configurations and is accepted for a wide array of applications. This shielding system will perform beyond the attenuation levels required for all major OEM’s.

RF Galvanized Panel System: The modular structure is traditionally used for high performance shielding. Panels are galvanized sheet steel bonded to a wood core that is attached via framing joints.

The RF panel system will be supported via threaded rod and dielectric isolators attached to the deck above. Shield will perform beyond the attenuation levels required for all major OEM’s

Auto-Latch RF Door: Provides security and access control for RF environments.

- Door security: The high-security latching mechanism ensures the door is secure and no person without access can enter.

- Door safety: The automatic door closer makes sure the door closes at all times. It works in tandem with the high-security latch to eliminate accidental walk-ins.

- Access control: The GT Auto-Latch doors electrical components allow for access control to only approved persons. It is compatible with all card-readers and keypad options.

- High-security lockset: Mul-T-Lock’s mechanical platform integrates advanced technology for premium security together with advanced & heightened key control.

Sliding RF Door: Our fully automatic Sliding RF Door features a completely pneumatic operating system and stainless steel design ideal for multiple bay operating suites.

This door is offered in single or double leaf designs and offers similar safety and security features as our Auto-Latch RF Door.

RF Shielded Window: These are factory fabricated double layer free of moiré pattern, non-reflective black coating with shielding equivalent to the enclosures.

RF Waveguide Air Vents: All HVAC access points into the RF shielded enclosure will be treated with a hex cell honeycomb waveguide vent assembly. The waveguide hex cell geometry is sized for optimal performance at the design specification.

Contact MarShield today for your MRI imaging room shielding needs. We will assist you in selecting the radiation shielding solution that best meets your requirements.

MarShield provides radiation shielding solutions for the medical and nuclear industries and is a division of the Mars Metal Company. Contact us today to discuss your unique radiation shielding needs.