Plasti-Shield® Borated Polyethylene Neutron Shielding is a lightweight, cost-effective neutron shielding solution

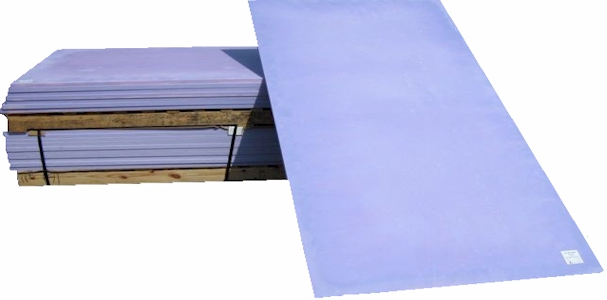

Stocking large inventory of 1” – 4’ x 8’ Borated and Pure Polyethylene Neutron Shielding Sheets & Pellets

Ready for immediate delivery and shipping within 48 hours.

From 1 sheet to 100 sheets in stock and ready to ship.

Custom cutting – any shape or size.

Custom Fabrication and CNC Machining Available

Lamination and custom assembly available.

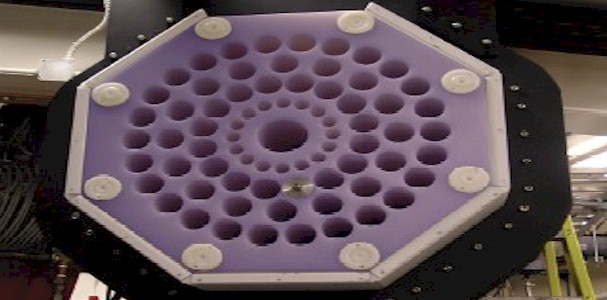

Plasti-Shield® Borated Polyethylene Neutron Shielding, supplied by MarShield, is a lightweight, cost-effective neutron shielding solution to attenuate and absorb neutron radiation. Our borated polyethylene contains 5% (2% available on special order) boron content by weight. Used in the medical, nuclear, and industrial marketplaces borated polyethylene is ideal for medical vaults and doors, particle accelerators, hot cells, nuclear storage and transport containers, and nuclear detection systems.

Most radioactive fields consist of different types of radiation. The most common include fast neutron, thermal neutron, primary gamma rays and secondary gamma rays. Plasti-Shield® is a borated polyethylene neutron shielding designed to attenuate these types of radiations.

- Fast Neutrons are most effectively shielded by hydrogen. Plasti-Shield® has an inherently high concentration of hydrogen, over 13% of volume.

- Thermal Neutrons are shielded by polyethylene with the presence of boron, such as Plasti-Shield® Industrial Grade with 5% boron by weight.

- Secondary Gamma Rays are created by the capture of thermal neutrons by hydrogen. These captured gamma rays can be minimized by adding boron, resulting in a significantly reduced energy dosage of only .42 MeV.

For easy installation, MarShield’s borated polyethylene neutron shielding comes in a standard sheet size of 48” x 96” x 1” thick. You can easily cut this polymer material using standard woodworking tools. Also available in pellet form.

FEATURES & BENEFITS

- Standard sheet size of 48″ x 96″ x 1″ thick (160lbs)

- Standard pellet size is 1/16” to 3/16” and available in 30 lb. bags or bulk

- Durable over a wide temperature range

- Consistent density and homogeneity

- Rated to MIL-P-23536A and EB2562E specifications

- Used as medical and industrial neutron shielding for more than 25 years.

- Light-weight, cost-effective and easily fabricated

- High cross-section for consistent neutron attenuation.

- Specific Gravity is 0.92.

APPLICATIONS

- Airport Security and Sea Port Security

- Medical Vaults

- Nuclear Reactors

- Nuclear Storage

- Nuclear-Powered Vessels & Vehicles

- Research Applications

- Linear Particle Accelerators

- Transport Containers

MATERIAL PROPERTIES

| Properties | Units | ASTM | Nominal Values |

|---|---|---|---|

| Density | g/cc | D1505 | 0.918 |

| Tensile Strength @ Break | % | D638 | >500 |

| Elongation @ Yield | p.s.i. | D638 | >1,400 |

| Flexural Modulus | p.s.i. | D790 | 30,000 |

| Durometer | Shore D | D785 | 42 |

| Notched Izod Impact | ft. lbs/in.2 | D256 | No Break |

| Vicat Softening Temp. | ºC (ºF) | D1525 | 89ºC (192ºF) |

| Brittleness Temp. | ºC (ºF) | D746 | <-76ºC (<-105ºF) |

| Heat Deflection Temp. 66p.s.i. | ºC (ºF) | D648 | 50ºC (122ºF) |

| Haze | % | D1003 | 12.7 |

| Dart Drop Impact Strength | g | D1709 | 130 |

| Elmendorf Tear Strength | g | D1922 | 340 |

MATERIAL COMPARISON

| Material | Density | Thickness |

|---|---|---|

| Water | 1.000 | 8.8″ |

| Concrete | 2.400 | 9.6″ |

| HD Concrete | 3.500 | 9.6″ |

| Plasti-Shield 5% | 1.040 | 8.0″ |

Also Available:

High-Density Pure Polyethylene Neutron Shielding

- High-density polyethylene (HDPE) with minimal impurities

- Neutron moderator with very high hydrogen content

- Available in slabs, cylinders, pellets, and can be easily machined into custom shapes

High purity polyethylene (HDPE) is used to thermalize fast neutrons, primarily for experimentation where it is desirable to produce a thermal neutron flux from a higher energy field. HP Polyethylene has minimal impurities that might absorb thermal neutrons.

Pure Polyethylene can be easily machined into complex shielding form factors and is available in virtually any shape or configuration. This material is often used in applications involving reactor physics, activation analysis, isotopic neutron sources and specially fabricated neutron casks.

Neutron Shielding – 30% Borated Polyethylene

- Contains 30% boron and relatively high hydrogen content

- Effective neutron shielding for criticality control applications

- Available in slabs, bricks, cylinders, and other custom shapes

Control of criticality is of the utmost importance during all phases of power reactor fuel handling, including reprocessing. In order to assure neutron isolation during these stages, shielding materials containing very high concentrations of boron are frequently used.

Borated Polyethylene 30 consists of polyethylene loaded with 30% natural boron. It contains 2.0 x 1022 boron atoms per cm3 and is typically used in applications such as criticality control where an effective thermal neutron absorber is required. It has a relatively high hydrogen content making it an effective fast neutron shield combined with a very high boron content for thermal neutron attenuation.

Borated Polyethylene 30 is available in slabs, bricks, and cylinders.

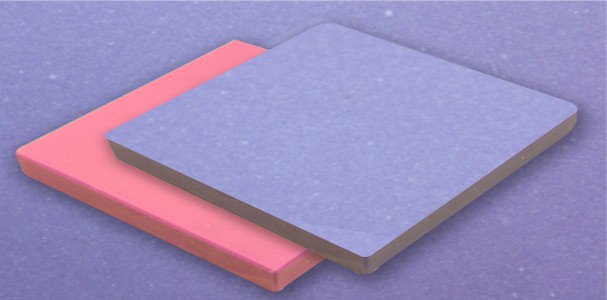

Plasti-Shield® is an effective shielding material with 5% boron by weight and our trademark purple color to meet all applicable applications for healthcare cancer treatment centers, diagnostic and hospital facilities. Applications include linear accelerators, nuclear or radiation shielding, industrial use, security such as seaports and airport security, nuclear submarines, nuclear power plants, border protection and other applications requiring attenuation of thermal neutrons.

Our process, materials, quality programs, sampling, testing, tracing and packaging all meet or exceed military specifications such as MIL-P23536A and EB2562E. We use MIL-STD-45662 for internal calibration system traceable back to NIST.

Dull finish on both sides.

Plasti-Shield® is available in 5% Purple and 2% Red is also available. Custom colors are available. Please call Customer Service at (800) 381-5335.

Yes. Please call Customer Service at (800) 381-5335.

Plasti-Shield® standard sheet size is 48” x 96”. Standard gauge is 1”. Custom sheet sizes and gauges available upon request. Please call Customer Service at (800) 381-5335.

- Neutron Shielding

- Our process, materials, quality programs, sampling, testing, tracing and packaging all meet or exceed military specifications such as MILP23536A and EB2562E with 2% boron only

Use standard woodworking tools: table saws, table routers, drills, blades and bits. Carbide router bits with two to four flutes are recommended.

- Store the sheets flat on a level surface

- Keep away from teak oil and other products that can stain the finish

- Use china markers or water-based markers to draw patterns

- Pen marks can usually be removed with household cleaners

- Keep away from heat sources that exceed 180°F

- Because there is no grain, parts can be cut from any area of the sheet

- Save the scraps for small parts, shims, spacers and plugs

- Airport Security and Sea Port Security

- International Border Security

- Doors for Linear Accelerators

- Medical Vaults

- Nuclear Reactors

- Nuclear-Powered Vessels

- Research Applications

Yes.

No, only small shavings.

![]() ”

”

Borated Polyethylene Information Sheet

Pure Polyethylene Information Sheet