MarShield manufactures lead bricks that are cast from 99.5% Minimum Pure Lead and are ideal for applications where maximum protection is required from X-Ray and Gamma Ray Radiation.

FEATURES & BENEFITS

Straight Bricks

- Can be cut on site in any direction

- Double stacked row configuration

- Fast assembly

Interlocking Bricks

- Easily erected, modified, disassembled, and relocated

- Unique interlocking “V” shape tongue and groove

- Tight fitting for enhanced radiation protection

- More stable space efficient wall system

We also offer machined and milled lead bricks in standard and custom sizes designed for specialized industrial and medical applications. All lead bricks can be painted matte black or grey epoxy and are available in special order colours. Corner lead bricks are also available where maximum radiation protection is required.

APPLICATIONS

- Cyclotron rooms

- Shielded walls, coves, and partitions

- Corner bricks and lead caves used for nuclear medicine/radioisotope applications

- Temporary shielding

- Transportation of radioactive material

- Hot cells

- Glove boxes

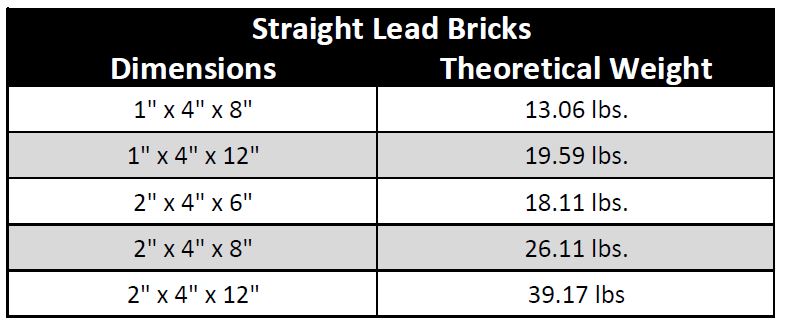

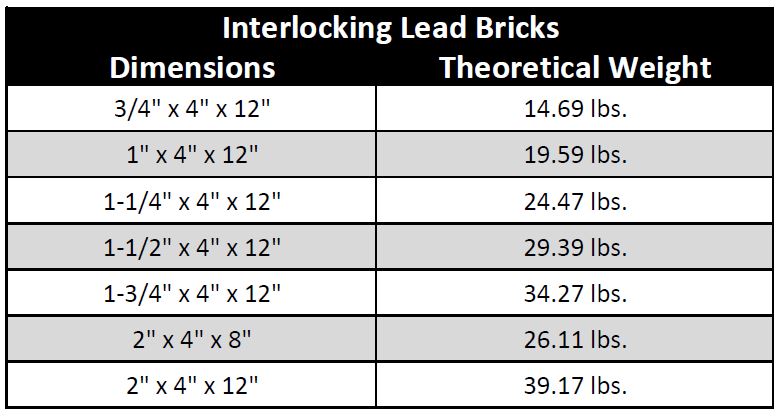

Our Straight and Interlocking bricks are available in a wide variety of sizes as shown below.

You can learn more about MarShield’s lead bricks here, or feel free to contact our product engineers anytime for a consultation. If you know what you need simply use our online RFQ form to specify your requirements and quickly calculate overall lead weight and volume.