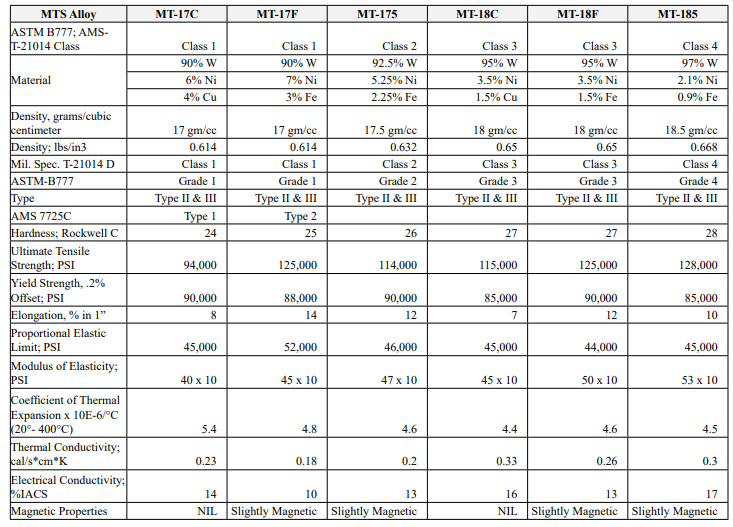

Tungsten Radiation Shielding for Nuclear, Medical & NDT

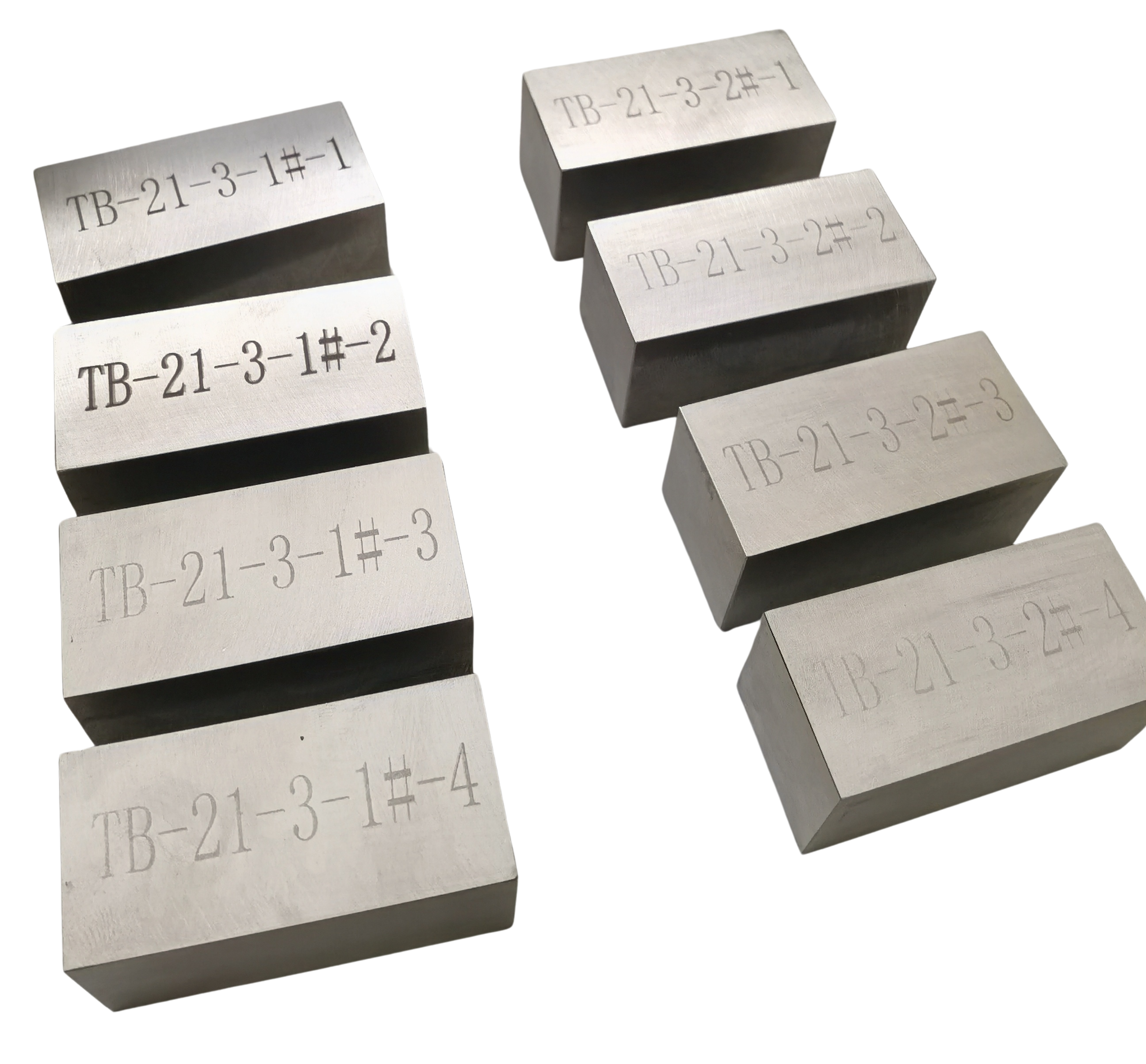

MarShield Radiation Shielding are experts in the customization of various tungsten heavy alloys which can be used in Nuclear Energy, Nuclear Medicine / Radioisotope, diagnostic imaging and non-destructive testing industries.

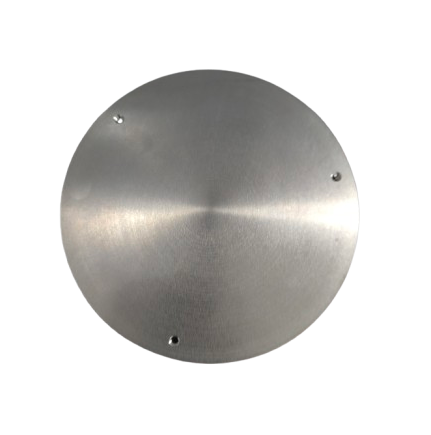

Limiting exposure to radiation is achieved by using materials that maximize shielding. The denser the material, the higher degree of shielding it provides. With a density approximately 1.7 timers higher than lead, Tungsten Heavy Alloy shielding guarantees radiation exposure is kept to a minimum. It is a viable option for many applications where lead is not feasible and is strong and highly customizable into precision components.

Why Tungsten?

When high degree of precision, dimensional accuracy, intricate, heat resistant, highly durable surface, Non-toxic and lead-free shielding against gamma and neutron radiation is critical, with a density of approximately 1.7 timers higher than lead (18.89 g/cm3 vs lead at 11.34 g/cm3) tungsten is a perfect choice to meet and exceed the safest shielding protection requirements.

Applications

Tungsten Heavy Alloy is the best choice for medical and industrial settings that require radiation shielding. It provides excellent value and uses less material than lead to provide the same level of absorption.

- High Energy Radiation Shielding – Nuclear, Medical & Industrial

- Counterbalance for Vibration Dampening

- Aircraft control surfaces

- Auto racing industry

- Boring bars

- Bucking Bars

- Down hole logging-Sinker bars

- Engine components

- Fire arms

- Golf club weights

- Helicopter rotor Systems

- Ship ballasts

Radiation Protection – Nuclear, Medical & NDT

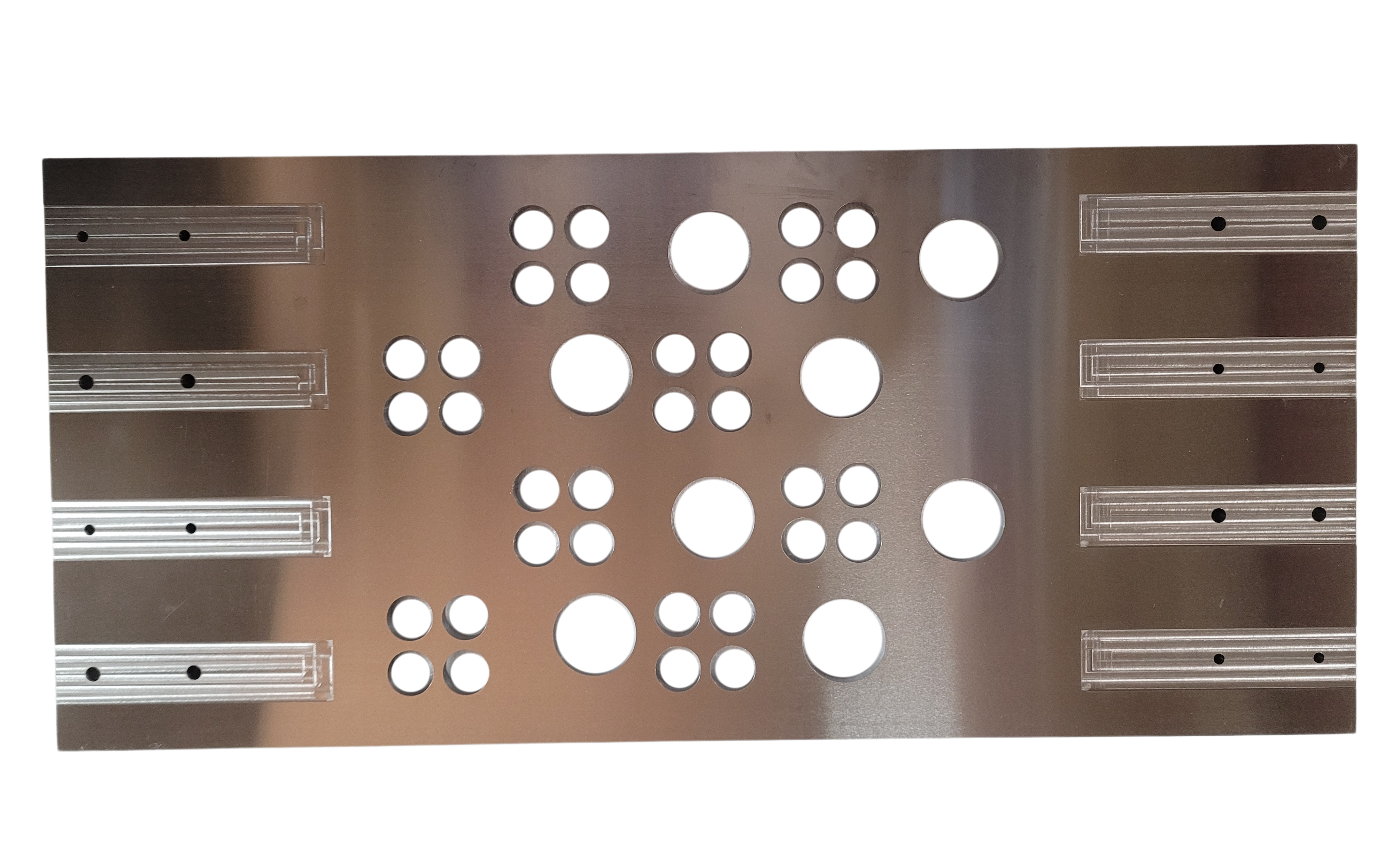

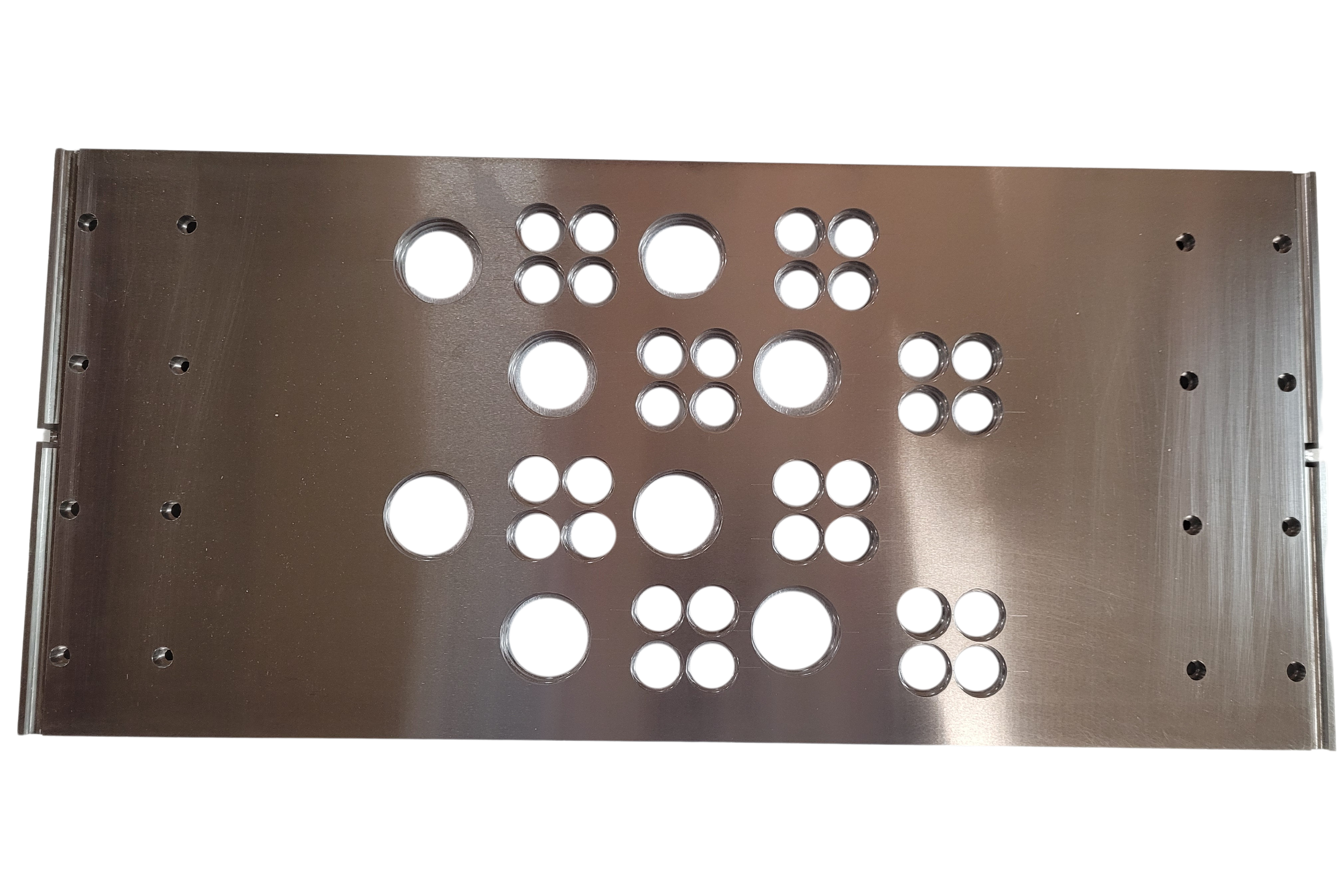

An excellent material for shielding, Tungsten Heavy Alloy guarantees minimum radiation exposure and ensures ALARA goals in the workplace. Machinability, radiographic density, strength, low toxicity, and heat resistance allow for superior design adaptability vs. other shielding materials.

Tungsten Heavy Alloy shielding is not subject to NRC, EPA, and OSHA regulations for special constraints and is used as:

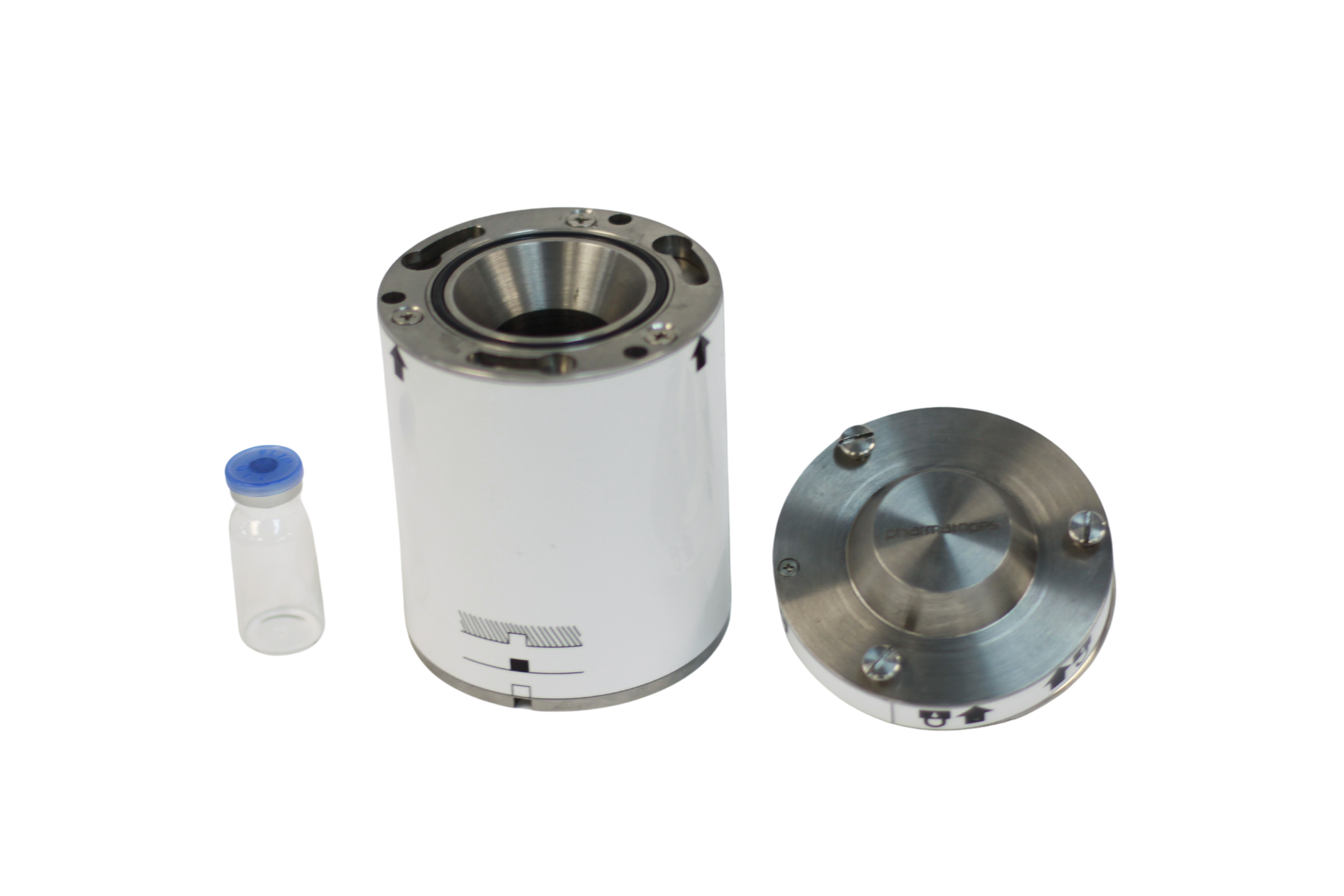

- Isotope vials and containers

- Custom shielding components

- Collimators for x-ray detectors

- Multi-leaf collimators

- Collimators for radiosurgery