MarShield specializes in delivering precision CNC cutting and waterjet cutting for borated polyethylene, a material essential for neutron shielding applications. Due to its high cost and specialized nature, customers often refrain from attempting to cut it on their own. MarShield addresses this challenge by offering value-added cutting services tailored to meet specific customer requirements.

Borated polyethylene is enhanced with boron, which helps absorb neutrons. This makes it an ideal choice for nuclear shields, medical vaults, and various industrial applications. Learn more about how Borated Polyethylene works here.

CNC Cutting Expertise Ensures Accuracy & Cost Savings

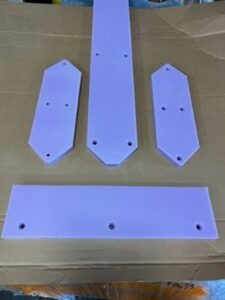

We utilize state-of-the-art 5-axis CNC machines to execute cuts based on customer-provided drawings. This approach allows for minimal material wastage by providing customers with exactly what they need without needing to purchase full borated polyethylene sheets. Our standard cutting tolerance is an impressive +/- 0.010″, which ensures high precision for specialized applications.

- Precision CNC cutting from customer provided drawings

- Our 5-axis CNC machine produces complex designs and 3-dimensional components.

- Our standard CNC cutting tolerance is +/- 0.010″.

- Waste reduction by providing only what is required, saving money on full sheets.

Types of Borated Polyethylene for Neutron Shielding

MarShield provides a range of other borated polyethylene solutions including various types of borated polyethylene for different radiation shielding requirements.

Explore our different options below:

High-Density Pure Polyethylene (HDPE) serves as an excellent neutron moderator due to its high hydrogen content, effectively thermalizing fast neutrons. This material is used primarily in experimental applications to produce a thermal neutron flux from a higher energy field. HDPE can be easily machined into complex shapes and is available in slabs, cylinders, pellets, and custom forms. It is typically utilized in reactor physics, activation analysis, isotopic neutron sources, and neutron casks.

Explore Borated Polyethylene Neutron Shielding.

30% Borated Polyethylene incorporates 30% natural boron, providing robust neutron shielding particularly suited for criticality control in nuclear fuel handling and reprocessing. This form effectively absorbs thermal neutrons while its high hydrogen content moderates fast neutrons. Available in various forms such as slabs, bricks, and cylinders, it is crucial for ensuring neutron isolation in sensitive nuclear applications.

Explore Borated Polyethylene Neutron Shielding.

Plasti-Shield Boron-Filled Polyethylene Shielding is a lightweight, cost-effective solution for neutron radiation protection. Its composition includes boron to optimize neutron absorption while maintaining a lightweight profile, which simplifies handling and installation compared to heavier traditional materials. This type of shielding is often used in applications in industrial, healthcare, cancer treatment centers, diagnostic and hospital facilities.

Plasti-Shield Boron-Filled Polyethylene Shielding is a lightweight, cost-effective solution for neutron radiation protection. Its composition includes boron to optimize neutron absorption while maintaining a lightweight profile, which simplifies handling and installation compared to heavier traditional materials. This type of shielding is often used in applications in industrial, healthcare, cancer treatment centers, diagnostic and hospital facilities.

Discover the advantages of Plasti-Shield.

Borated Polyethylene Pellets offer a flexible and customizable approach to radiation shielding. These pellets can be molded or extruded into various shapes and sizes, providing manufacturers with the capability to create tailored shielding solutions for specific applications. This versatility makes them ideal for unique and intricate designs where traditional shielding forms may not be feasible.

Borated Polyethylene Pellets offer a flexible and customizable approach to radiation shielding. These pellets can be molded or extruded into various shapes and sizes, providing manufacturers with the capability to create tailored shielding solutions for specific applications. This versatility makes them ideal for unique and intricate designs where traditional shielding forms may not be feasible.

Learn more about Borated Polyethylene Pellets.

Custom Cut Borated Polyethylene From MarShield

Borated polyethylene is versatile and can be used in several critical areas, including medical radiation therapy rooms, nuclear power plants, and research facilities where radiation protection is mandatory. We can assist in a variety of borated polyethylene solutions, including custom-cut borated polyethylene to fit your specific requirements.

MarShield has successfully completed multiple custom borated polyethylene projects, with customers expressing satisfaction with the quick lead times, excellent finishes, and competitive pricing. Our process not only meets the exacting standards required in critical applications but also supports clients in achieving cost efficiency and material optimization.

Reach out to our team to discuss your custom cut borated polyethylene needs.