By: Chris Newman

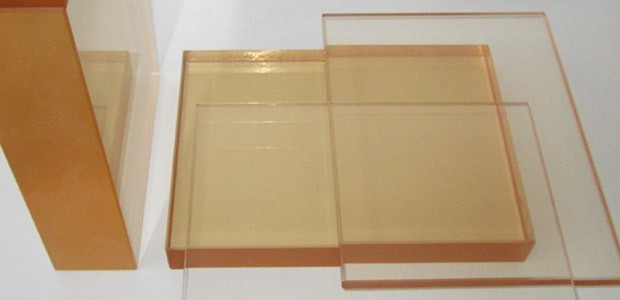

Leaded acrylic is a shatter-resistant, versatile solution to your radiation shielding needs. The transparent plastic contains 30% lead by weight, combining superb light transmission with effective radiation protection.

MarShield, an industry leader in radiation shielding materials, carries a variety of sizes and thickness of leaded acrylic and can fulfill custom orders according to the requirements of a client. Leaded acrylic can be used in a variety of applications, including X-ray rooms, control booths, laboratories, dental clinics, veterinary clinics, medical diagnostic screens, eye protection lenses, and materials testing.

Key Features of Leaded Acrylic

- Available in six different lead equivalencies and thicknesses

- Made from acrylic polymer resin into which lead is chemically introduced as an organ-lead salt compound

- Can be cut, drilled or machined using standard plastic-handling techniques

- Provides complete radiation protection with unmatched design flexibility

- Ideal for any radiation shielding application

One of the key benefits of leaded acrylic is the open feel environment it creates while at the same time providing reduced exposure to harmful radiation. A healthier and happier work environment is established as leaded acrylic has a high light transmission.

A more rugged and durable alternative to lead glass, the transparent leaded acrylic is less reflective and has less glare on the surface. It is also easier to ship and less likely to break when moved.

MarShield has conducted extensive research and development to ensure that our shielding products provide comprehensive protection in any medical or technical research application.

MarShield Custom Radiation Shielding Products provides radiation shielding solutions for the medical and nuclear industries and is a division of Mars Metal Company.

Contact us today to discuss your unique radiation shielding needs!