MarShield was contracted by a large commercial construction company to build accelerator doors for a cancer care facility in Washington, USA. We were brought on board due to our expertise in fabricating and installing accelerator doors.

What made this particular project unique was that one door was to be installed immediately to get an accelerator room operational and the second door was to be installed at a later date.

We began the fabrication process working with the physics report provided by the customer to custom design a set of doors. Adjustments were made on our approval drawings and the doors were designed to the customer’s exact specifications to ensure installation on-site would be smooth.

Accelerator Door Specifications

The total weight of each door was 12,588 lbs with an opening/closing time cycle of 36.3 seconds. The door was equipped with a Brookfield operating system, fully compliant with UL 325 and ANSI 156.10 for swing doors weighing up to 20,000 lbs. Brookfield door operators and W150-HD Brookfield hinges were also installed.

Each door was 65.5 inches in width, 87.0 inches in height, and 16.625 inches thick. The door was lined with 4” of lead brick, 83,000 lbs per door and 10’ of 5% Borated Polyethylene.

The door came with a custom 4” diameter push plates for push open, push close, and partial open feature that would allow it to operate in case of a power outage. Safety sensing edges were put in place to prevent someone or something from getting pinched in the door.

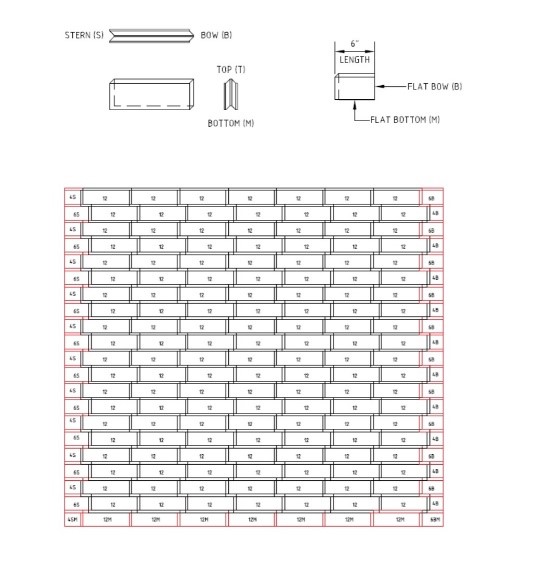

MarShield ensured complete radiation coverage during construction of our doors by cutting and labelling all of the bricks to sit flush in the door. Cutting and labelling the bricks before they were shipped to site allowed us to install the door quickly and ensure a fast turn around so that the room could be operational as quickly as possible.

If you have any questions on how an accelerator door can be designed for your needs, you can visit the MarShield website or contact us, and we will help find the best solution for you.