A long-established U.S.-based supplier of nano-optical and X-ray components needed a custom shielding solution for cleanroom product testing. The challenge was to install a compact, structurally sound enclosure inside a cleanroom environment, where products undergo radiation testing prior to shipment.

The client required more than radiation shielding. The solution had to be easily cleanable, low-maintenance, and compliant with both safety and sterility requirements. MarShield was selected for our ability to design and deliver highly customized shielding systems that align with regulated environments and technical performance standards.

Designing for Cleanroom Compliance and Radiation Safety

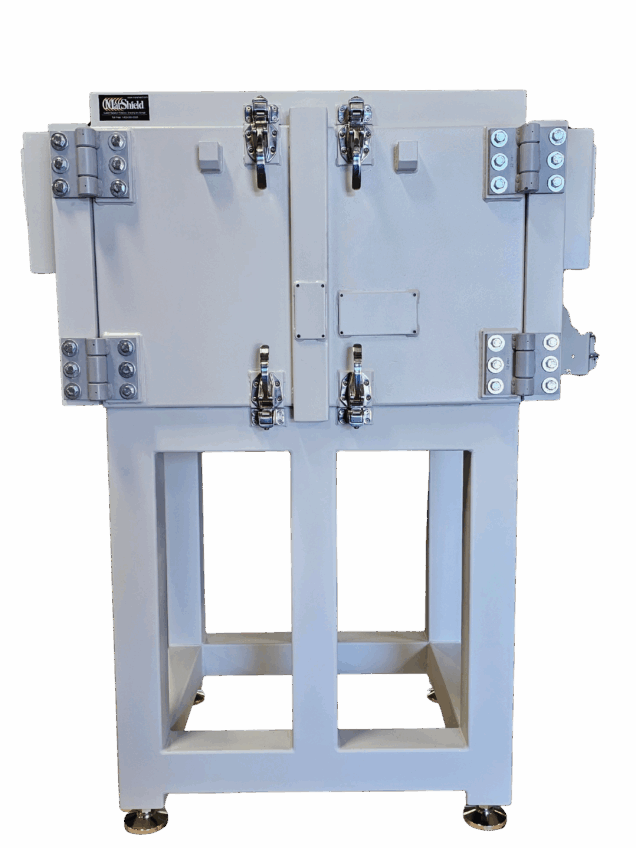

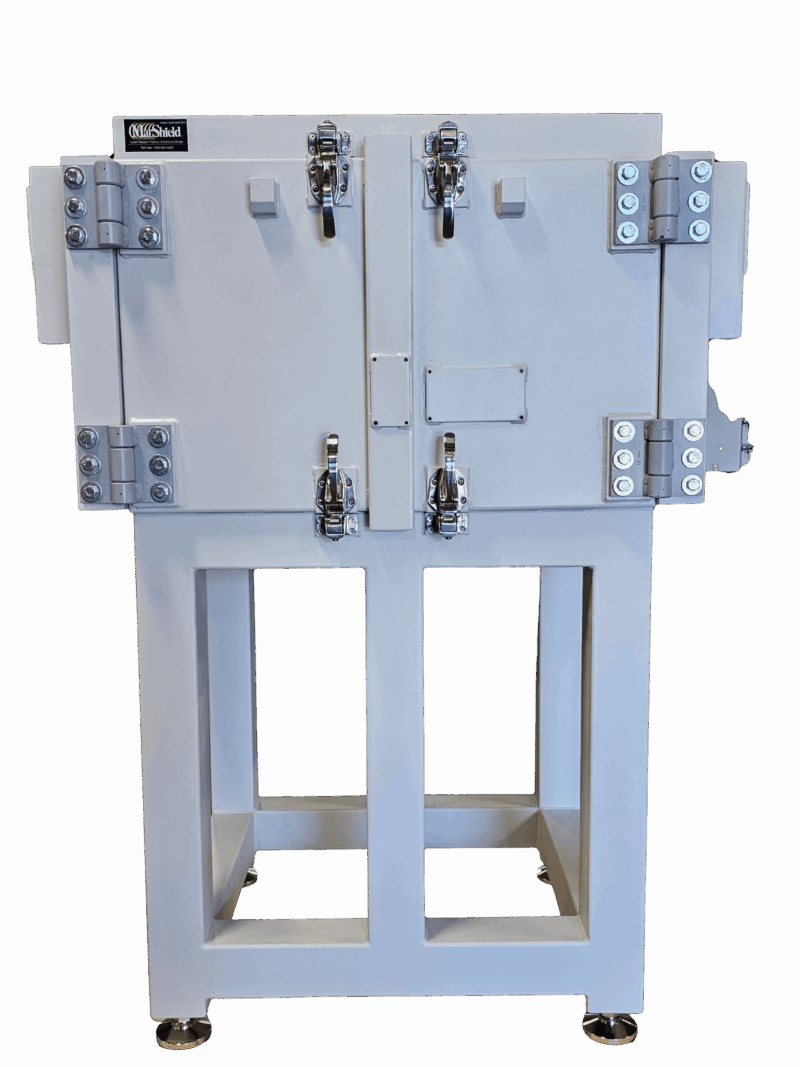

To meet the strict operational and sterility standards of a cleanroom testing environment, we engineered a fully enclosed leaded shielding system designed for both radiation protection and contamination control.

At the core of the enclosure is a ¼” thick lead barrier, encapsulated between sheet metal. This configuration provides reliable radiation attenuation while maintaining structural integrity over time. To align with cleanroom hygiene protocols, the exterior was finished with a custom smoothed paint coating, allowing for frequent wipe-downs and minimizing particle buildup that could compromise testing conditions.

The cabinet measures 34 inches wide, 28 inches deep, and 24 inches high, with a total height of approximately 64 inches. This compact footprint fits cleanroom environments efficiently without requiring structural changes.

We reinforced the structure with forklift-compatible base supports, adjustable leveling feet, and anti-tip wall tabs, ensuring the unit can be securely transported and anchored without risking tilt or vibration during operation.

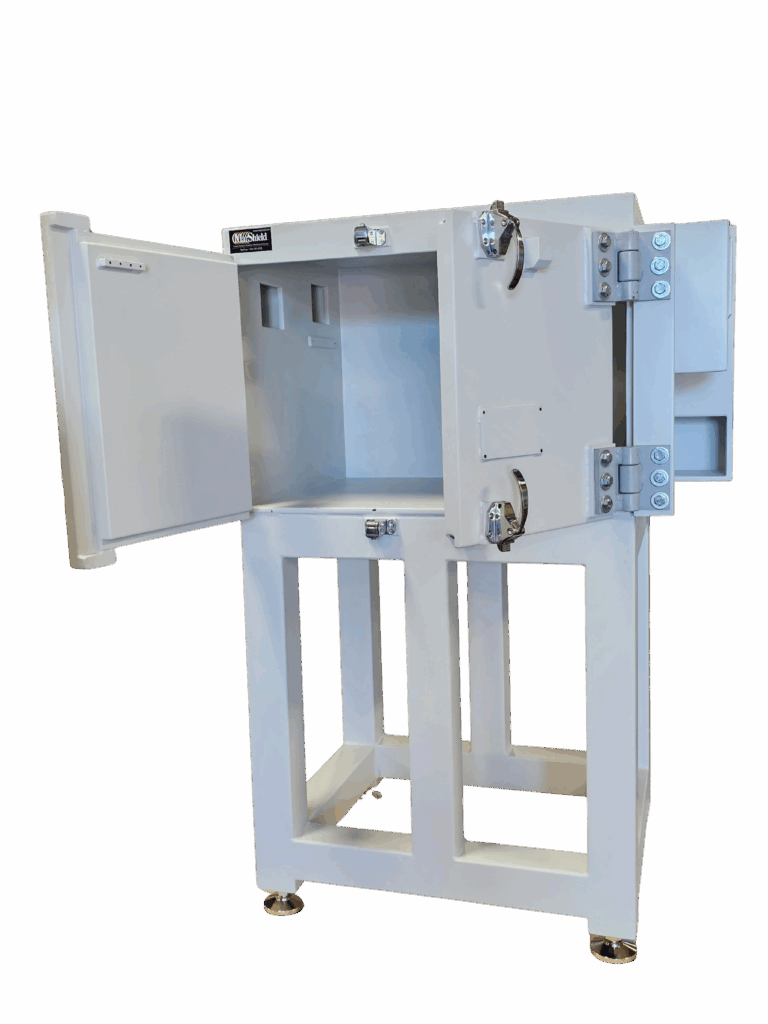

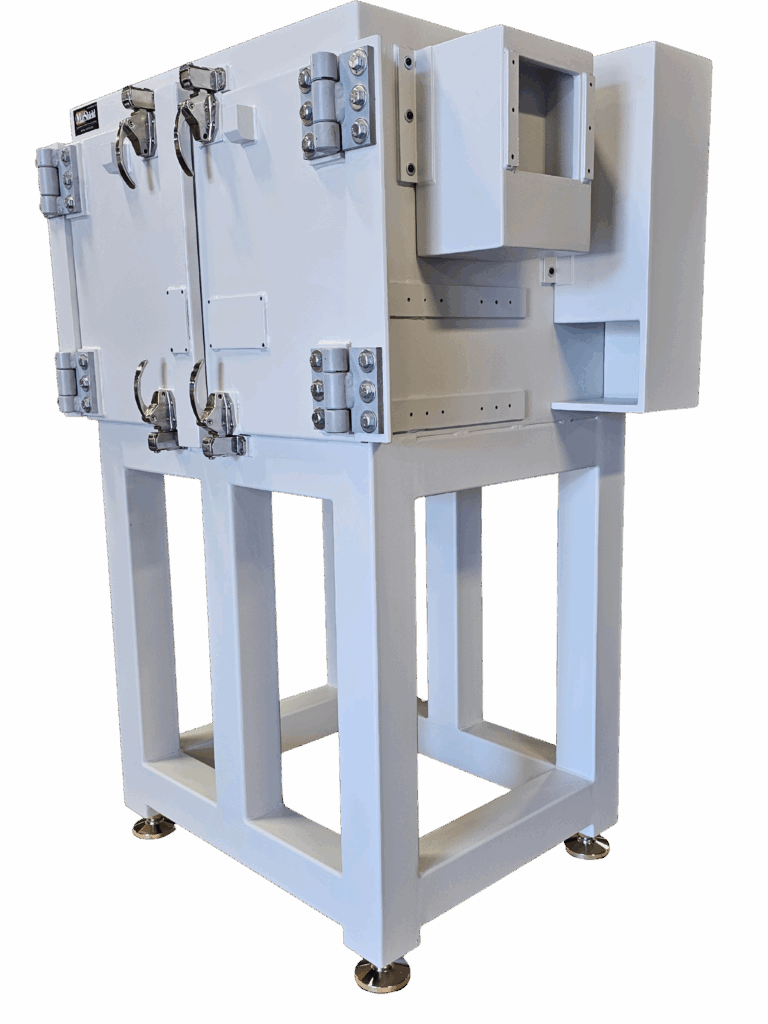

The unit includes airflow and wire chases with a three-bounce layout, allowing for ventilation and cable routing while maintaining radiation shielding across key entry points. The enclosure also includes internal brackets for sensor mounting and a ¼-20 threaded grounding lug to support electrical grounding requirements.

For routine service, the unit includes pin-hinged doors and removable side panels, giving technicians quick, safe access while maintaining shielding integrity.

For routine service, the unit includes pin-hinged doors and removable side panels, giving technicians quick, safe access while maintaining shielding integrity.

This lead lined enclosure was not only engineered to perform under radiation, but also to withstand the daily demands of a sterile, high-precision environment where control, safety, and reliability are non-negotiable.

The Result: Operational Control, Safety, and Compliance

The enclosure enabled the client to:

- Test X-ray emitting products safely in a sterile, enclosed environment.

- Reduce contamination risk with an easy-to-clean, low-texture finish.

- Meet radiation protection protocols while preserving cleanroom sterility.

- Prevent workflow disruptions through modular, service-friendly access.

- Extend service life with a durable, transport-ready structure.

This project reinforced our role as the go-to shielding partner for high-risk, regulated environments. Designed with precision and built for cleanroom performance, the solution met technical and sterility standards, proving that safety never has to come at the expense of usability.

Precision Shielding for Regulated Industries

MarShield continues to support clients in highly regulated environments with shielding solutions tailored to specific workflows, operational risks, and installation settings. Whether it’s for radiation testing, medical imaging, nuclear energy, or industrial safety, our enclosures are designed to protect people, products, and processes at every stage.

Need shielding that integrates with your cleanroom, lab, or testing process?

Let’s design a solution that meets your performance, compliance, and maintenance goals.