MarShield was tasked by a leading Canadian nuclear research institute to design and manufacture a custom shielded box that met very specific requirements for radiation shielding. This project was critical due to the sensitive nature of the client’s work, demanding high precision and adherence to stringent specifications.

Precision Shielding Requirements for Nuclear Research

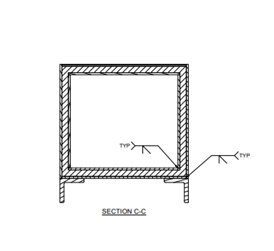

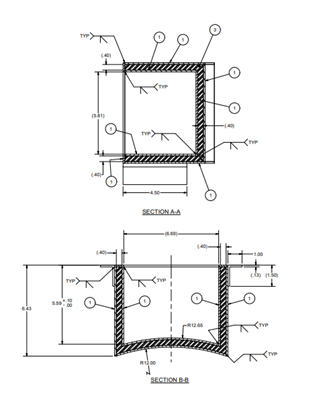

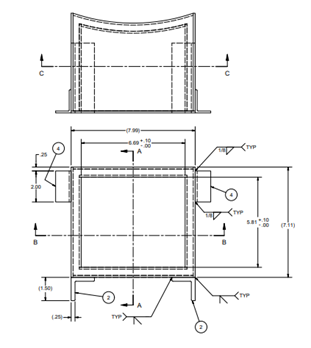

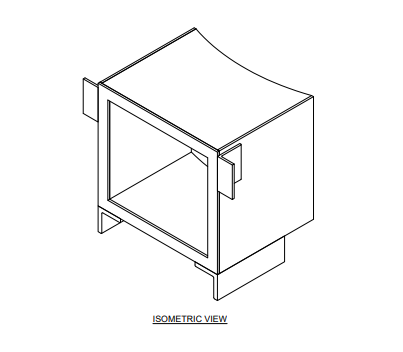

The institute required a custom-built shielded box that not only met their high standards for safety and efficacy but also matched precise installation criteria. The shield had to be constructed with an aluminum encasing and integrated lead plates to ensure effective radiation shielding. Furthermore, the box was required to fit seamlessly under existing equipment, necessitating a curvature radius on the top side to align perfectly with the existing setup. One of the significant challenges was the stringent timeline set by the client, requiring an accelerated production process without compromising the quality or precision of the final product.

MarShield’s Custom Radiation Shielding Solution

The MarShield team worked closely with the client, engaging in a thorough consultation process to outline all technical requirements and design specifications. This collaborative approach ensured that the final design was fully aligned with the client’s needs before moving forward.

The MarShield team worked closely with the client, engaging in a thorough consultation process to outline all technical requirements and design specifications. This collaborative approach ensured that the final design was fully aligned with the client’s needs before moving forward.

Upon receiving final approval for the design, MarShield’s production team swiftly commenced the manufacturing process. To meet the high standards expected by the client, the following key project components were prioritized:

- Dimensional Tolerance: Ensuring that all components of the shielded box adhered strictly to the specified dimensions was paramount.

- Accuracy: The entire project demanded high accuracy to ensure that the shielding effectiveness and the physical fit of the box met the client’s exacting standards.

- Attention to Detail: MarShield maintained stringent quality control throughout the manufacturing process. Each stage of production was monitored, and comprehensive final inspections were conducted to guarantee that every aspect of the shielded box met the required specifications.

Successful Outcomes & Customer Satisfaction

The custom shielded box was successfully delivered on schedule and exceeded the client’s expectations in terms of both functionality and quality. MarShield’s expertise in custom metal fabrication and radiation shielding was crucial in navigating the project’s complexities, resulting in a product that was precisely tailored to the client’s needs.

The institute praised MarShield for its commitment to quality and the team’s ability to meet a demanding schedule. The client was particularly impressed with the seamless integration of the shielded box with their existing equipment.

MarShield’s Expertise in Custom Nuclear Radiation Protection Products

This project highlights MarShield’s capability to handle highly specialized, precision-oriented projects within the nuclear research sector. The successful delivery of the custom shielded box not only provided the client with an essential component for their research operations but also reinforced MarShield’s position as a leader in the field of radiation shielding solutions.

For more information on our custom solutions, visit MarShield Custom Radiation Shielding Products.