LX PREMIUM : Premium Radiation Shielding Glass

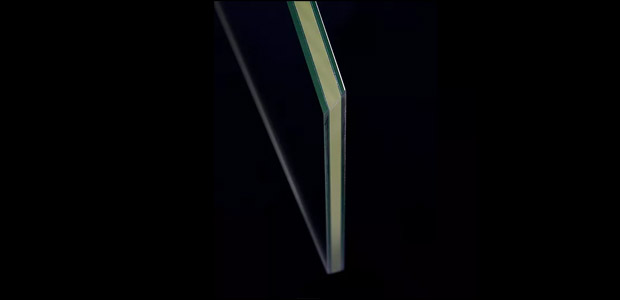

LX Premium is the next generation of radiation shielding glass. It has a multilayer structure, manufactured by inserting LX-57B high-lead glass between panels of protective sheet glass. This results in a glass surface that will not stain or discolour, even in contact with chemicals or if it is wiped with a wet cloth.

LX Premium has a multi-layer structure, manufactured by inserting LX-57B lead glass between two panels of protective sheet glass. Thus, the standard outer glass panels will not stain or discolor, even in contact with harsh chemicals or if cleaned improperly.

LX Premium is easily maintainable. Having evolved from conventional radiation shielding lead glass, it represents the next generation of radiation shielding glass with excellent impact and shatter resistance.

In certain instances, improper cleaning of standard LX-57B lead glass can cause fogging and staining. This can also occur when standard LX-57B lead glass surfaces are touched by bare hands (transferring sweat or lipids), when wiped with a water soaked cloth, splashed with any bodily fluids, or when certain harsh cleaning products/chemicals are applied. Having extra layers of protection prevents fogging or discoloration due to improper care and cleaning.

Sizes Available Up To 48″ x 96″

14-16 Week Lead Time (special order only)

6 Week Lead Time – Additional Cost

High transparency

Because the lead glass is protected by outer sheet glass, the glass surface will not fog (which refers to discoloration or staining caused by lead substances reacting to moisture or lipids) even when chemicals adhere to its surface or it is wiped with a wet cloth. Easy to maintain!

Excellent maintainability

Because it is protected by outer sheet glass on both sides, the glass can be cleaned using such items as a wet cloth, glass cleaners, and detergents without any concern about fogging, staining or discoloration. You would clean LX Premium the same way you would clean ordinary windowpanes.

Safety

Because it is a multi-layer laminated glass of LX-57B and outer sheet glass, it is impact-safe and shatter resistant.

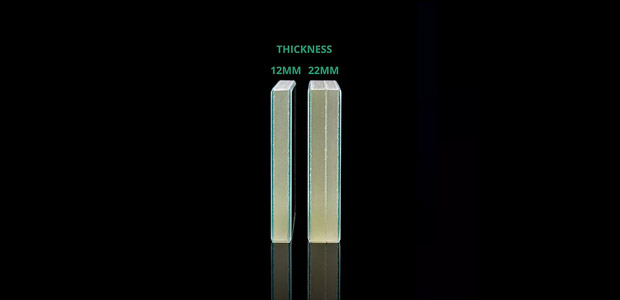

| Thickness (mm) | 12mm | 14mm | 20mm | 22mm |

|---|---|---|---|---|

| Lead Equivalent (in) | *1/16″ | *5/64″ | *7/64″ | *1/8″ |

| Lead Equivalent (mmPb) | 1.6 | 2.0 | 3.0 | 3.3 |

| X-Ray Tube Peak (kV) | 150 | 150 | 200 | 200 |

| Thickness Tolerance | ±1.2mm | ±1.4mm | ±1.4mm | ±1.4mm |

| Weight (lbs/sqft) | 9 | 11 | 12 | 15 |

*Lead equivalent is guaranteed in (mmPb). The converted fraction (in.) is less than the lead equivalent (mm Pb); fraction is approximate.

- Knoop Hardness: 520

- Light Transmittance (at 550nm): More than 80%

LX-57B (Middle Layer):

- Minimum density: 4.36 (g/cm³)

- Refractive index (Nd): 1.71

- Thermal expansion coefficient: 80 X 10-7 /°C (30- 380°)

Outer Layers: Special Cover glass.

Inter Layer: LX-57B is a lead barium type glass of high optical grade with over 60 percent heavy metal oxide, including at least 55 percent PbO. It offers high light transmission and does not discolor due to radiation.

*Lead equivalent is quaranteed in (mmPb). The converted fraction (in.) is less than the lead equivalent (mmPb); fraction is over-coverage.

To calculate the values of the range of “Lead Equivalent (Ibs/sq.ft.)”, we converted from the values of the range of “Lead Equivalent (mmPb)” using the mentioned figures and rounded off the fractions to one decimal place: 1 foot = 30.48cm / 1 pound = 453.59 g/Density of lead = 11.3 9g/cm3). Thickness tolerance can be up to +/- 1.3mm.

Uses and Applications

- Window of an X-ray control booth that requires sterilization

- Observation window for an angiography room or anywhere chemicals are likely to spatter

- Inspection window of a door that is frequently touched by people