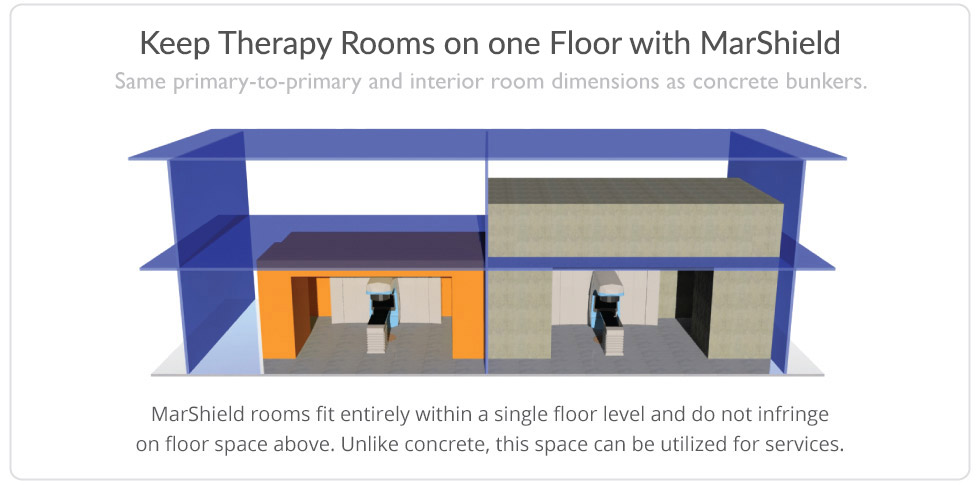

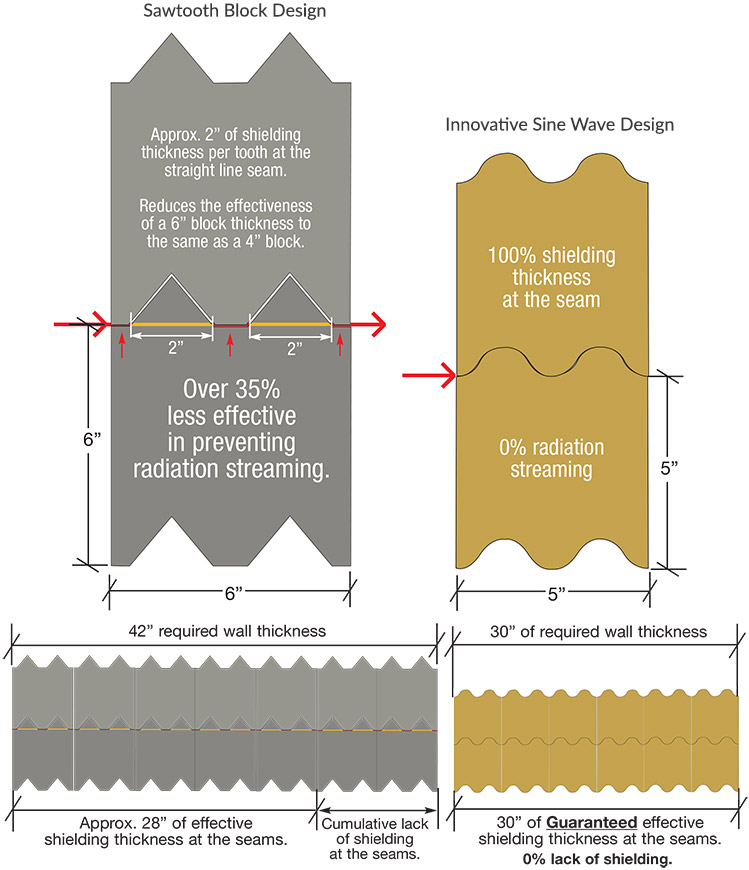

MarShield’s system of dry stacked shielding modules which interlock to form a tight, leak-free therapy room of any size or shape. Unique sine-wave shapes eliminate straight line seams and provides superior neutron, photon and particle attenuation at the joints. Available in four densities – 150, 220, 250 and 300 lbs./cu.ft. (2.4, 3.52, 4 and 5 g/cu.cm.). MarShield construction requires half the space of mass concrete vaults.

-

Features & Benefits

- Easy and quick to, install, remove, and re-install if necessary.

- MarShield offers smaller sizes for lighter weight and easier handling.

- Construction is not labor intensive, design is flexible, and does not omit hazardous dust emissions during installation.

- Blocks are environmentally safe to handle and use with no disposal concerns as material is non toxic.

- Blocks are dry stacked

- Accelerated depreciation

- No concrete curing time

- Little to no steel reinforcement and no formwork

- Space saving offer regular concrete

- Easy to transport and store on worksite, unaffected by weather.

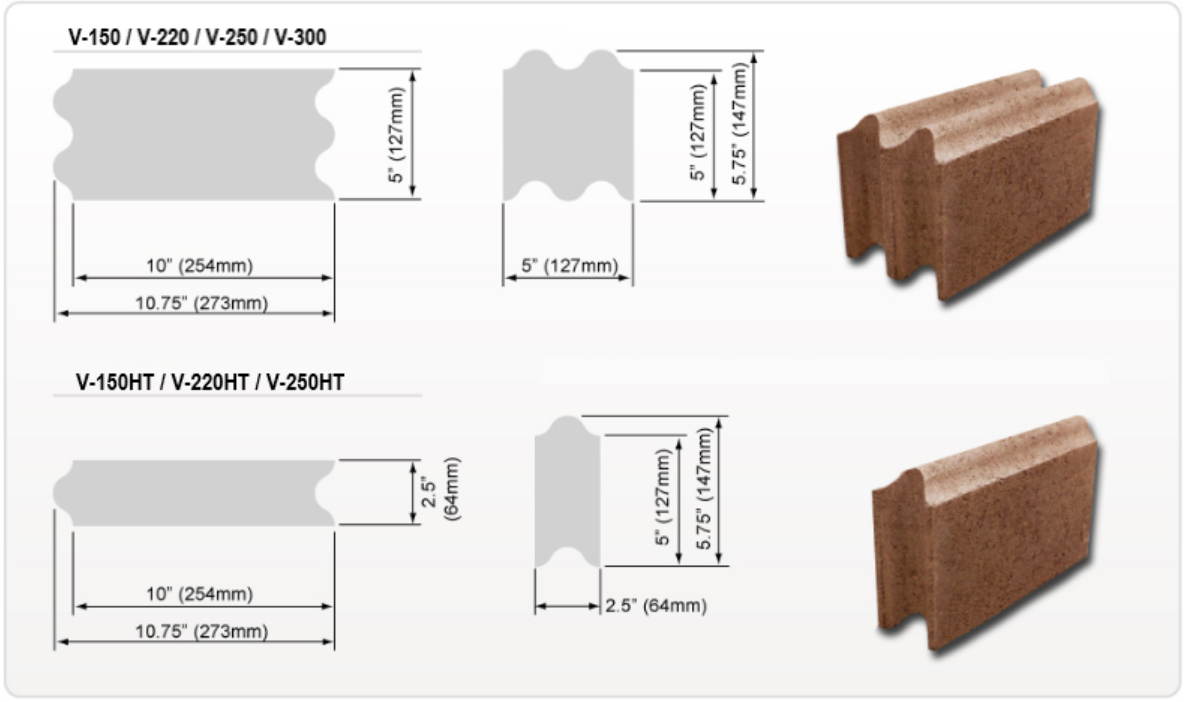

Standard MarShield blocks are 5” x 5” x 10” (127 x 127 x 254mm). Block are also available in half thicknesses, with a nominal thickness of 2.5 inches (63 mm).Compressive strength is guaranteed to meet 2,800 psi. This product routinely easily surpasses this minimum and is typically on the order of 5,200 psi. Grout materials will have a lesser compressive strength as water content is increased for working properties, but shall not be less than 2,800 psi when mixed on site.

-

MarShield V Pack

Dramatically cut installation time

Individual MarShield modules are assembled into stackable packs to form a standard V Pack unit. Simply craned into position V Pack brings added speed, simplicity and efficiency to the construction of any size radiation shielded structure. The larger and more massively shielded the structure, the more V Pack can positively impact the construction process. In proton facilities, V Pack provides the perfect alternative to time-consuming concrete construction by cutting months off the average construction schedule.

-

Construction/Placement

Simplified installation process – Craned and placed into position using a minimal-sized crew. No manual handling of individual blocks – No curing time – Ready immediately for the next stage of construction – Shielding is not a critical path element.

| Model No. | Description | Face Length | Face Height | Thickness | Density |

|---|---|---|---|---|---|

| V-150S | Standard | 10″ (254mm) | 5″ (127mm) | 5″ (127mm) | 150 lbs./cubic ft. (2.4g/cubic cm)* |

| V-220S | Standard | 10″ (254mm) | 5″ (127mm) | 5″ (127mm) | 220 lbs./cubic ft. (3.52/cubic cm)* |

| V-250S | Standard | 10″ (254mm) | 5″ (127mm) | 5″ (127mm) | 250 lbs./cubic ft. (4g/cubic cm)* |

| V-300S | Standard | 10″ (254mm) | 5″ (127mm) | 5″ (127mm) | 313 lbs./cubic ft. (5g/cubic cm)* |

* Nominal weight and density

* All models except V-300 are available in Half Thickness (HT) size

-

MarShield High-Density Block

-

Concrete

![]() ”

”

High Density Concrete Information Sheet